What is Sweating Slab Syndrome?

Sweating Slab Syndrome (SSS) is a common issue in industrial facilities where moisture in the air condenses into liquid on concrete floors. This condensation happens when warm, humid air cools below its dew point temperature, often due to contact with cooler surfaces. In industrial environments, the largest and most temperature-sensitive surface is typically the concrete slab floor.

As warm, moisture-laden air meets the cooler slab, water vapor condenses on the surface. Compounding the problem, oils and hydrocarbons from machinery and rubber tires can clog the slab’s porous surface. This prevents the concrete from absorbing and releasing moisture effectively. If the surface remains cool and lacks sufficient heat energy to re-evaporate the moisture, water begins to pool—creating a slick, hazardous surface.

Why Sweating Slab Syndrome Matters

SSS turns your concrete floor into a slippery, dangerous surface—especially in facilities with heavy foot traffic, forklifts, and machinery. It poses a serious safety risk, increases the likelihood of workplace injuries, and can impact productivity and operations.

How to Prevent or Minimize Sweating Slab Syndrome

1. Air De-stratification

Industrial buildings often experience air stratification, where layers of warm, humid air form at higher elevations and cooler, denser air settles near the floor. Each layer has different temperatures and humidity levels, contributing to uneven dew point conditions.

Installing High Volume Low Speed (HVLS) fans helps mix these layers into a more uniform air mass. This blending process—called de-stratification—balances heat and moisture throughout the space. As a result, the risk of localized condensation on the slab is greatly reduced, since fewer cold spots develop on the floor.

2. Keep Floors Clean and Porous

Regular cleaning of concrete floors is essential. Oils, greases, and debris reduce the slab’s natural porosity, limiting its ability to absorb moisture. Maintaining clean, breathable concrete allows the slab to manage small amounts of condensation more effectively and discourages pooling.

3. Control and Optimizing Outside Air

Introducing outside air is a necessary part of ventilation in most industrial buildings, typically managed through makeup air units and exhaust systems. This exchange of air, called an air change, helps remove stale, humid indoor air and replace it with fresher outside air.

However, unmanaged outside air can introduce extreme conditions—too humid, too hot, or too cold. These sudden changes can destabilize indoor environments and worsen SSS.

The solution? Smart controls.

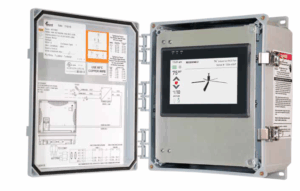

By installing sensors to monitor outside humidity, temperature, dew point, and enthalpy, you can make data-driven decisions about when and how much outside air to bring in. Comparing these values to indoor air conditions enables precise air change timing for optimal energy efficiency and indoor air stability.

Use Floor Slab Sensors

For next-level control, add slab temperature sensors to your building automation system. These sensors detect when the slab drops below the dew point of the surrounding air—a key trigger point for condensation. With this data, your system can automatically activate HVLS fans to mix and warm the air, raising the slab temperature and preventing moisture accumulation.