Modine Make-Up Air Units

Make-up air systems are designed to replace air that’s been exhausted from a space, helping maintain building pressure, air quality, and temperature control. In facilities like gyms, cafeterias, warehouses, or garages, where large volumes of outdoor air are required, selecting the right type of system is essential

Indirect vs. Direct Fired Units

An indirect fired system uses a burner that heats a heat exchanger, which then transfers warmth to the air passing over it. The key point is that combustion products never mix with the conditioned air. This design is ideal when clean, separated airflow is needed. Indirect systems typically offer 82% efficiency and allow recirculated air, making them suitable for a wider range of applications, especially where codes limit direct exposure to combustion air.

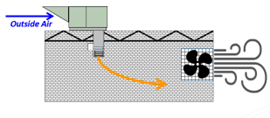

A direct fired system, however, heats air directly in the combustion stream. High volumes of outdoor dilution air are introduced to maintain safe indoor air quality. These systems offer 100% thermal efficiency and excellent turndown capability, down to 4% of its capacity. Since combustion air mixes directly into the space, direct fired systems are not permitted in sleeping quarters or some tightly regulated environments.

Performance & Application Differences

Both direct and indirect system types cover similar airflow ranges, from 800 to over 14,000 CFM, and can handle high air temperature rise requirements, up to 100 °F for indirect and 130 °F for direct fired. Cooling options, including evaporative and DX cooling, are available for both system types, with Modine offering factory-installed DX coils starting Summer 2025.

Indirect systems offer greater application flexibility due to their sealed combustion design. They’re often used in areas with specific air purity needs or code restrictions. Direct fired systems excel in high-capacity heating with fast response times, ideal for industrial or commercial space needs 100% outside air at high efficiency.

Updated Features & Controls for 2025

Recent updates to Modine’s product line include factory-installed VFDs on all three-phase motors (1–5 HP), standard starting January 2025. Controls have also improved. The optional Modine Control System uses a microprocessor for programmable operation, BACnet compatibility, fault diagnostics, and easier user interface navigation. While basic electromechanical controls are still available, the advanced system offers better flexibility and feedback.

Factory-installed DX coils for R-32 and R-454B refrigerants will also be available in summer 2025. These come with refrigerant sensors and built-in mitigation strategies, like shutting down burners or compressors and opening dampers in the event of a leak, which is another layer of safety built into the latest units.

Simplifying Product Selection with Breeze

Modine’s Breeze software makes equipment selection fast and accurate. The tool filters options based on project criteria like airflow, external static pressure, and heating capacity. It also provides detailed submittals, job-specific performance data, BMS variables, and blower curves. When using Breeze, it’s important to include only customer-side static pressure—not Modine accessories—in your calculations.

Choosing between indirect and direct fired make-up air systems comes down to application needs, local codes, and performance goals. Indirect systems offer cleaner air separation and application flexibility, while direct fired systems deliver higher efficiency and output for 100% outdoor air applications.

With new control options, DX cooling features, and accelerated selection tools, Modine’s newest updates make it easier than ever to specify the right unit for your job.