Proper layout and placement of unit heaters is critical to achieving efficient, uniform heating in commercial and industrial spaces. A well-planned layout not only ensures comfortable working conditions but also maximizes energy efficiency and reduces operational costs. Whether you are designing a heating system for a warehouse, manufacturing floor, or large open space, attention to heater placement can make a significant difference in system performance.

Locating Unit Heaters

- Select the quantity of units based on heat distribution and application

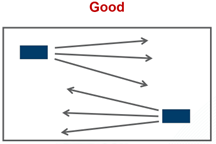

- Locate to maintain proper air distribution

- Support air stream from other heaters

- Minimize air stream interference

- Mount at proper height

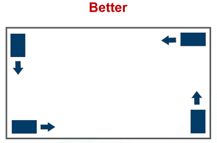

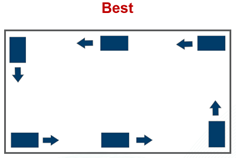

Layouts for Unit Heaters

The ideal layout design should have the heaters located in a “racetrack” design along the walls of the building.

Practical Guidelines to Consider for a Unit Heater Layout

- Divide the Space into Heating Zones

- Large buildings should be broken into logical heating zones (by usage, orientation, occupancy) so you can control each area independently.

- Allows you to reduce heating in less critical areas, saving energy.

- Mounting Height & Air Throw

- Most unit heaters have a specified throw distance and mounting height.

- As a rule of thumb, 7-9ft off the finished floor gives good warm-air distribution in most industrial spaces

- Always check the manufacturer’s throw chart: hanging too high or too low can create cold spots

- Spacing Between Heaters

- Typical spacing is 1.5-2x the rated throw distance

- g., if heater throws are effectively 20ft, space units roughly 30-40ft apart

- Stagger units so their airstreams overlap to avoid gaps of unconditioned air.

- Typical spacing is 1.5-2x the rated throw distance

- Locate Near the Exterior Walls or Doors

- Placing heaters along cold walls or near large doors minimizes drafts and cold-wall effects

- If you have high-traffic doors, mount a heater above or beside it to keep the entrance area warmer when the door is open

- Avoid Obstructions & Dead Zones

- Keep the airflow path clear: avoid placing units behind racking, large process equipment, etc.

- Check for overhead cranes or hoists that may interfere with mounting or airflow

- Allow for Service Access & Clearances

- Follow manufacturer’s recommended clearances on all sides

- Leave adequate space about the unit for piping and wiring

- Consider Supplemental Air Circulation

- In very tall spaces, add circulating fans (e.g., HVLS fans) to destratify.

- Most unit heaters have a specified throw distance and mounting height.

- Large buildings should be broken into logical heating zones (by usage, orientation, occupancy) so you can control each area independently.

A well-designed heater layout takes strategic planning to support air movement, accommodate building features, and meet the demands of your specific environment. By dividing large spaces into zones, mounting heaters at the correct height, spacing them effectively, and accounting for things like exterior doors, and other obstructions, you lay the foundation for a system that performs efficiently and reliably.

Keep in mind that every building is different. What works in one space may need to be adjusted in another. Always refer to manufacturer recommendations and consult air throw charts before finalizing your layout. When in doubt, supplement your system with destratification fans to help reduce hot air buildup at ceiling level.